Are you looking for an efficient and reliable solution to meet the growing demand for ice cream cones? Our semi-automatic wafer cone machine, namely the small cake cone machine, is a kind of ice cream cone-making machine specialized in making wafer cones.

This wafer ice cream cone machine can make dozens of shapes of cones, and its operation method is very simple, the price is also very favorable. This machine is an ideal choice for small and medium-sized ice cream shops, dessert shops, cafes, and bakeries

What Is a Semi-automatic Wafer Cone Machine?

A semi-automatic wafer cone machine is equipment used to bake and form wafer ice cream cones through manual operation and mechanical heating. Compared with fully automatic models, this machine offers a more economical investment while still maintaining reliable output and flexibility.

It features heating plates, baking moulds, manual lever controls, and an integrated electric system for temperature and time adjustment. Operators manually close and open the moulds, making it ideal for small factories, new businesses, or users who require multiple cone shapes.

Wafer Ice Cream Cone VS Crisp Ice Cream Cone

Ice cream cones are just a general term. In fact, there are many types of ice cream cones on the market, but they are mainly divided into two categories, namely wafer cones and crispy cones. What is the difference between a wafer ice cream cone and a crisp ice cream cone?

- The formula is different. The recipes and ingredients for processing these two ice cream cones are different. Usually, the sugar content in the raw materials for making crispy cones is higher than the sugar content in the raw materials of the wafer cones.

- The baking temperature is different. Different ice cream cone machines are usually used to make wafer cones and crispy cones, and the baking temperature of the cones during processing is also different.

- The taste is different. Wafer cup cones are usually soft in texture, not easy to break, and taste sweet and soft. Crispy cones are usually crisp and hard in texture, crispy in the mouth, and can be made into various flavors.

This wafer cone machine is specially designed for producing wafer cones and wafer cups. Wafer cones have a light, thin, and crispy texture. If you need to produce thicker and harder crispy/sugar cones, we recommend considering our sugar cone making machine.

Ice Cream Cone Making Machine Features

- This semi-automatic wafer cone machine is small in size, compact in structure, convenient to move, and at a favorable price. It is very suitable for small and medium-sized food processing plants and ice cream factories.

- The heating method of the ice cream cone machine is electric heating. Its operation method and maintenance are very simple, safe and reliable. The output is 50-1800pcs/h.

- There are many models and types of this machine. We can recommend the most suitable product model for customers according to their production needs and investment budget. In addition, we can also customize the size of the egg cone required by the customer according to the customer’s needs.

- It supports various standard wafer cone shapes, such as the classic cup shape, elegant torch shape, and unique horn shape, meeting the needs of different markets.

- We can also provide customized molds based on your specific requirements. Whether you need special dimensions or unique patterns (such as a brand logo or customized designs), we can create molds for you to produce exclusive, branded wafer cones.

Classifications of Taizy Ice Cream Cone Making Machine

This cake cone machine is designed with different numbers of baking molds, mainly 2 molds, 4 molds, 10 molds, 12 molds, 24 molds, 32 molds, 40 molds, and 60 molds.

Technical Parameter of All Semi-automatic Wafer Cone Maker

| Model | TZ-2 | TZ-4 | TZ-10 | TZ-12 | TZ-24 | TZ-24C | TZ-32 | TZ-32C | TZ-40 | TZ-60C |

| Number of molds | 2 | 4 | 10 | 12 | 24 | 24 | 32 | 32 | 40 | 60 |

| Capacity | 50-60 | 100-120 | 250-300 | 300-350 | 600-800 | 600-800 | 800-1000 | 800-1000 | 1200-1400 | 2400-3000 |

| Baking time(minute) | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 |

| Operating method | Manual | Manual | Manual | Manual | Manual | Manual | Manual | Manual | Manual | Manual |

| Power(kw) | 1.5 | 2.4 | 4.5 | 6.5 | 12 | 12 | 15 | 15 | 18 | 21 |

| Voltage(v) | 220 | 220 | 220 | 220 | 220/380 | 220/380 | 220/380 | 220/380 | 220/380 | 220/380 |

| Net weight(kg) | 45 | 80 | 200 | 180 | 280 | 350 | 320 | 450 | 580 | 850 |

| Dimension(mm) | 450*350*700 | 530*350*650 | 760*600*1050 | 800*700*880 | 1050*800*900 | 730*800*1370 | 1200*800*900 | 880*880*1380 | 1080*800*1440 | 1260*1140*1640 |

Various Models of Wafer Cone Makers

How Does the Wafer Ice Cream Cone Making Machine Work?

Before using this ice cream cone making machine, we need to turn on the power of the machine and preheat the molding system of the machine to about 150°C. Of course, we also need to use a batter beater to mix the raw materials into a batter.

Then immerse the container into the batter so that a certain amount of batter enters each hole of the container. Next, place the container above the forming mold of the wafer cone machine, and align each material hole with each egg tube forming hole, open the feeding device, and the batter will be poured into the forming hole.

Then pull the wrenches on both sides of the machine to press the forming mold into the forming hole for baking. The baking time will last about 1-2 minutes. After the egg cone is baked, push the wrenches on both sides of the machine upwards, the forming mold will be raised, and then pull another set of wrenches, the forming plate will open, and the finished egg cone will automatically fall into the discharge port of the machine.

Wafer Cone Machine Operation Video

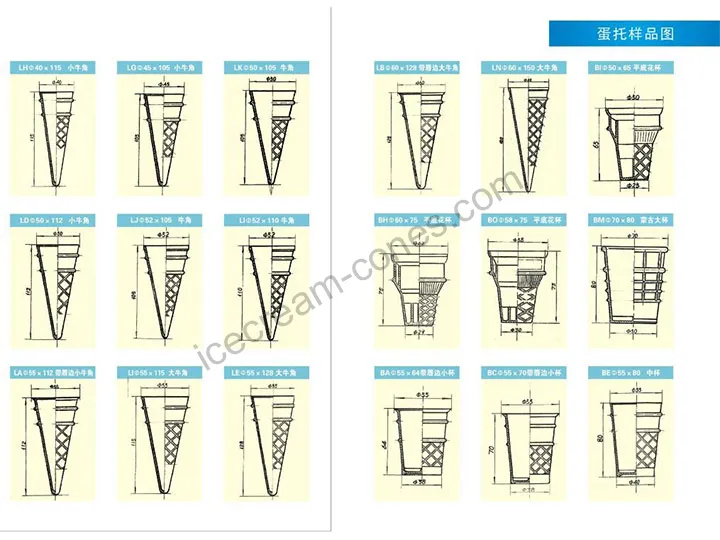

Cone Shapes That the Semi-Automatic Wafer Cone Machine Can Make

Standard Cone Shapes

- Cup Shape: Suitable for soft ice cream machines and scoop ice cream

- Torch Shape: The most common traditional ice cream cone

- Sugar Cone / Pointed Cone: Popular among commercial ice cream brands

Special Cone Shapes

- Horn Shape: Ideal for premium desserts or creative ice cream shops

- Flower Cup / Petal Shape: Attractive look for cafés, dessert shops, and beverage stores

- Wafer Bowl: Suitable for ice cream, fruits, yogurt, and desserts

Mini and Special-purpose Cones

- Mini Cone: Used for catering desserts, party snacks, or small retail packs

- Snack Cone: Designed for fillings like chocolate creams, nuts, or syrups

Fully Customizable Cone Shapes

One of the biggest advantages of a semi-automatic wafer cone machine is full mould customization, including:

- Custom cone height, top diameter, and bottom size

- Custom surface patterns (wave lines, grids, stripes, etc.)

- Logo embossing for brand identity

- Special-shaped cones (heart-shaped, square, oval, etc.)

Simply provide a sample or design drawing, and a custom mould can be made.

Applications of the Wafer Cone Machine

The semi-automatic ice cream cone making machine is suitable for:

- Ice cream factories

- Pastry and snack manufacturers

- Food processing workshops

- New dessert businesses or startups

It can produce a wide range of cones including ice cream cones, waffle cups, mini cones for snacks, and specialty cones used in bakery products.

Ice Cream Wafer Maker Price

The ice cream wafer maker price depends mainly on machine type, mould quantity, production capacity, and customization requirements. Semi-automatic wafer cone machines are generally more affordable than fully automatic models, making them ideal for small to medium-sized factories.

Basic semi-automatic models with standard moulds typically range from entry-level economical prices to mid-range industrial prices, depending on the number of heads (such as 16, 24, 32, or customized moulds). If you need special cone shapes, logo-engraved moulds, or higher output, the price will adjust accordingly.

To provide an accurate quotation, suppliers usually ask for:

- Desired cone size and shape

- Required output per hour

- Voltage requirements

- Whether custom moulds are needed

By sharing your production needs, you can quickly receive a personalized price list and choose the machine that best fits your budget and business scale. You may leave a message on our website or contact us via WhatsApp.