The fully automatic sugar cone production line, also called waffle ice cream cone production line, is the large waffle cones processing equipment that can make large-volume crisp ice cream cones. The output of this continuous sugar cone making machine is between 2500-7500 per hour.

Technical data of the sugar cone production line (gas-heating)

| Model | TZ-37 | TZ-45 | TZ-55 | TZ-65 | TZ-75 |

| Capacity | 3000-3500pcs/h | 3500-4000pcs/h | 4500-5000pcs/h | 5500-6250pcs/h | 7000-7500pcs/h |

| Power | 2.2KW | 2.2KW | 3KW | 3KW | 3KW |

| Voltage | 380V 50Hz 3phase | 380V 50Hz 3phase | 380V 50Hz 3phase | 380V 50Hz 3phase | 380V 50Hz 3phase |

| Gas consumption | 140cube/24hours | 160cube/24hours | 200cube/24hours | 240cube/24hours | 280cube/24hours |

| Dimension | 6.5*1.8*1.75m | 8*1.85*1.8m | 9*1.9*1.85m | 10*1.9*1.85 | 11*1.9*1.85m |

| Total weight | 4200kg | 4700kg | 5100kg | 6000kg | 7100kg |

Note: In order to save production costs, the fully automatic sugar cone processing line uses gas heating to bake the cones. Gas heating can use natural gas heating and liquefied gas heating.

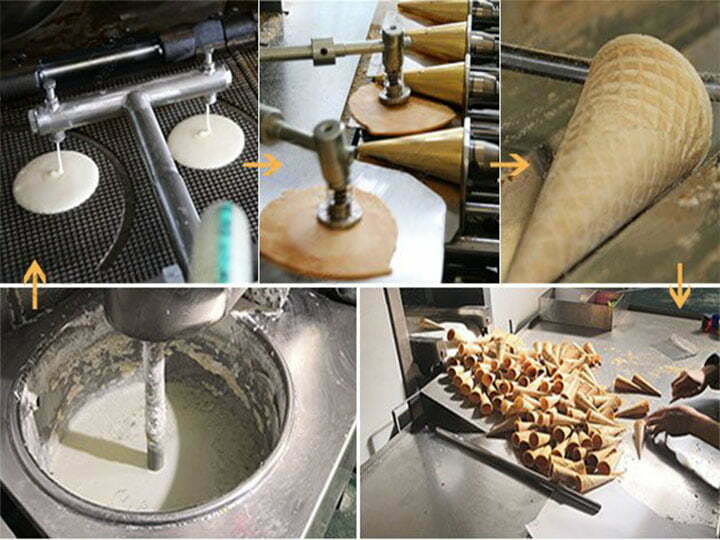

How does the large waffle cone making machine work?

1. Paste battering and mixing. The batter mixer barrel will quickly mix the raw materials, such as low-gluten flour, butter, milk, eggs, sugar, etc., to form a dough with a uniform concentration.

2. After the batter is made, the grouting device of the automatic waffle cone machine will extract a certain amount of batter, and inject the batter into each baking tray in the machine in turn through the grouting pipe and grouting nozzle.

3. The sugar cone production line has multiple baking trays inside, which move circularly inside the machine during baking. The baking temperature of sugar cones is between 130°C and 160°C, and the baking temperature can be adjusted as needed.

4. The baked dough will be quickly transported to the automatic forming system of the waffle cone machine for further processing. The molding system is mainly composed of multi-component molds, which can quickly make the baked dough rolls into a certain shape. Common shapes are sugar cones with flat edges and crisp cones with lace edges.

5. After the ice cream cone is processed, it will automatically fall on the conveyor belt at the bottom of the machine, and then be automatically sorted into rows by the V-shaped sorting table, and finally manually collected for packaging.

Video of ice cream cone machine working process

Supporting device for large waffle cone production line

1. Cooling conveyor

The cooling conveyor is mainly used to neatly arrange and transport the produced products to the assembly workshop.

Specification: 5mx0.65mx0.7m

Voltage (Voltage): 220V

Power (Power): 0.75kw

2. Sorting table

This device is mainly used to superimpose sugar cones into strings, which is convenient for counting and packing into boxes.

Specification: 1.5mx0.45mx0.7m

Machine material: 304 stainless steel

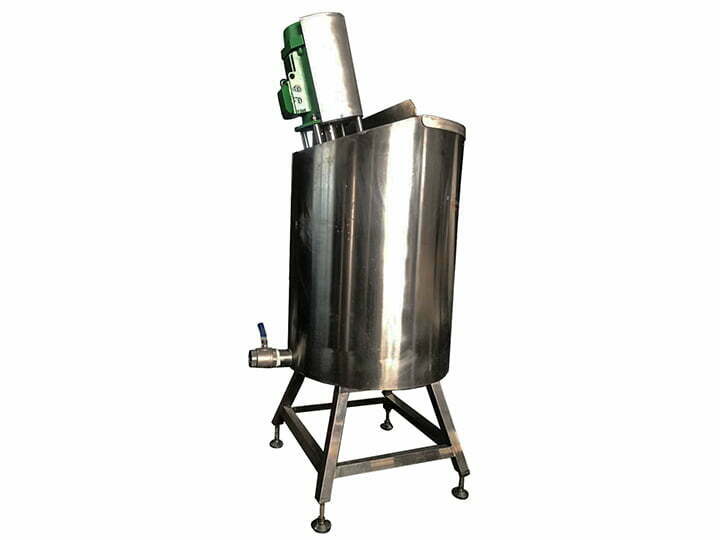

3. Paste mixer

The batter mixing barrel is mainly used to break up the raw materials, stir and fully mix. There is a motor on the top of the mixing barrel, which can drive the mixing shaft in the barrel to run at high speed.

Applications of the full-automatic sugar cone production line

The commercial sugar cone making machine has a large output, so it is very suitable for large and medium-sized food processing plants, ice cream factories, individual enterprises, restaurants and large chain stores. The waffle and ice cream cone business is very profitable. The ice cream cones that can be processed by the waffle cone machine are flat-sided cones and lace-sided cones that are common in the market.

How to start an ice cream cone business in your country?

Contact Taizy right now! We have professional engineers and sales managers. You can tell us your final product, expected capacity, plant area, and other demands of the ice cream cone machine. Our sales manager will design and provide you with a good solution. If you are interested in the Taizy ice cream cone-making machine, please put our website in your favorites. We will update more customer cases and machines!

Why choose Taizy automatic sugar cone production line?

- Experienced. Taizy is a manufacturing and sales company with ten years of experience, and we help our customers to produce food better and faster. We provide automatic sugar cone-making machines and semi-automatic ice cream cone machines. For customers who want to invest in a suger cone production line, we welcome you to visit our company and factory. It is important to have a site visit to the machine in order to get a better understanding of the structure and the way it is produced.

- Professional team. A professional sales team and engineering team help you to choose the best machine for you, they are patient and will reply to customers’ questions in time, you can trust them and tell them your needs.

- Taizy will provide perfect after-sales service. The sales manager will send photos and videos of the delivery to the customer and follow up the logistics throughout the process of the ice cream cone machine being shipped. After the customer receives the machine, we will provide installation instructions and how to use it.