The crisp ice cream cone machine also called the crisp egg roll machine and crisp sugar cone machine, which is a kind of cone processing machine commonly used in ice cream processing plants. This kind of ice cream cone making machine needs to be matched with a paster, mixer, cone forming machine, etc., to make crisp ice cream cones of various shapes and sizes in the automatic sugar cone production line. The output of a semi-automatic ice cream cone is 500-1200pcs/h.

What can the semi-automatic ice cream cone machine do?

The semi-automatic ice cream cone making machine has a wide range of uses and is more practical. Therefore, many small ice cream factories will choose to purchase this machine to produce crisp ice cream cones. It should be noted that this cone processing machine can only make crisp cones, but not wafer cones.

Common crispy ice cream cones on the market can be made with this equipment, such as flat-sided ice cream cones, lace ice cream cones, waffles, sunflower-shaped cakes, egg rolls, and bowl-shaped cones.

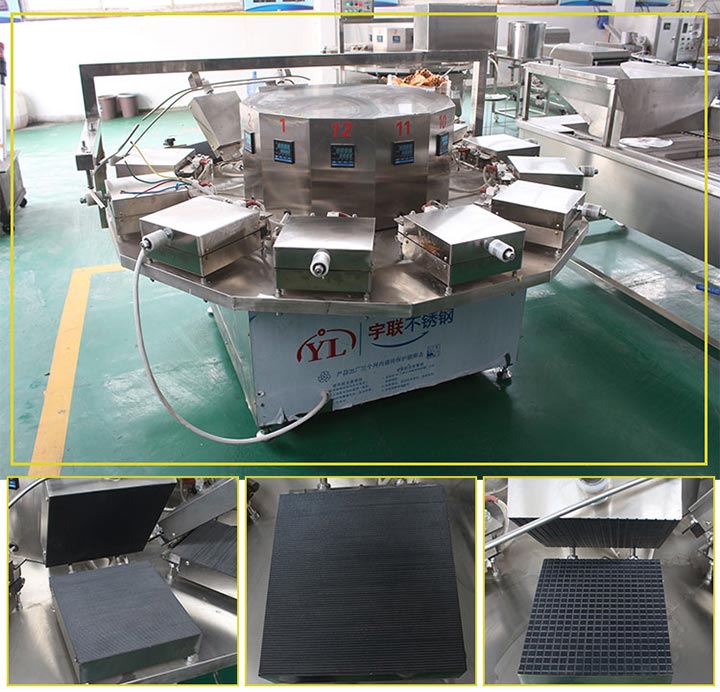

Crisp sugar cone machine structure

The semi-automatic ice cream cone machine introduced here is mainly composed of four parts: batter beater, grouting barrel, baking host, and cone forming machine.

Batter Beater: It‘s inner mixing shaft can fully mix various raw materials for making ice cream cones, such as low-gluten flour, butter, sugar, salt, eggs, milk, flavor, etc. into a batter.

Grouting bucket: The grouting bucket is mainly used to hold the dough and quantitatively inject the grouting onto the ice cream cone baking host.

Cone baking host: The automatic baking host is generally designed as 6-18 independent baking trays. The baking temperature can be adjusted according to customer needs.

Ice cream cone forming machine: Cone forming machine is mainly to make the baked cakes into various shapes of ice cream cones. Different shapes of ice cream cones can be made by changing different forming machines.

Optional heating method for crisp ice cream cone maker

As a professional ice cream cone machine manufacturer, the semi-automatic ice cream cone making machines in our Taizy factory are generally designed with two heating methods, namely gas heating and electric heating. The reason for using these two heating methods is to meet the needs of more customers.

1. Electric heating type crisp waffle cone machine

The electrically-heated ice cream cone machine uses electricity as the heat source so that each baking tray can be heated evenly. And according to the thickness and size of the egg rolls and cones to be made, the baking temperature can be adjusted.

Technical parameter:

| Model | TZ-6 | TZ-9 | TZ-12 | TZ-15 | TZ-18 |

| Piece thickness(mm) | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| Piece size(mm) | 7-20 | 7-20 | 7-20 | 7-20 | 7-20 |

| Capacity(pcs) | 300 | 400-600 | 600-800 | 800-1000 | 1000-1200 |

| Power(kw) | 10 | 14.5 | 19 | 23 | 28 |

| Dimension(cm) | 140*140*125 | 160*160*125 | 170*170*125 | 180*180*125 | 190*190*125 |

| Weight (kg) | 250 | 270 | 300 | 330 | 360 |

2. Gas heating type crisp sugar cone machine

The gas-heated crisp waffle cone machine largely meets the needs of customers in areas with insufficient electricity supply and more expensive electricity. And when the output is large, the gas-heated ice cream cone making machine is more cost-effective. Gas heating is divided into two methods: natural gas heating and liquefied gas heating.

Technical parameter:

| Model | TZ-09 | TZ-012 | TZ-015 | TZ-018 |

| Piece thickness(mm) | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| Piece size(mm) | 7-20 | 7-20 | 7-20 | 7-20 |

| Capacity(pcs) | 400-600 | 600-800 | 800-1000 | 1000-1200 |

| Natural gas(m³) | 0.6 | 0.8 | 1.1 | 1.4 |

| Liquefied gas(kg) | 0.9 | 1.2 | 1.4 | 1.6 |

| Dimension(cm) | 185X185X170 | 195X195X170 | 205x205x170 | 215x215x170 |

| Weight (kg) | 450 | 550 | 650 | 750 |

Semi-automatic ice cream cone machine’s working process

First of all, we need to add the raw materials to the batter beater for rapid mixing to make a batter.

Then, put the batter into the grouting bucket, and an air compressor is connected under the grouting bucket, and the batter in the grouting bucket can be injected into each baking tray quantitatively.

Before baking, we usually have to preheat the egg cone baking host in advance. Therefore, when the batter is poured into the baking pan, the baking starts immediately. The baking temperature can be adjusted between 140℃-200℃.

Then, after about one rotation (about 1 minute), the egg rolls or cones are baked. The lid of the baking tray will automatically open with the guide rails. At this time, the cakes on the baking tray must be taken out manually.

Since the cake just taken out is softer, it can be molded into different shapes. Therefore, we can use automatic forming machines to process egg rolls and egg cones into various shapes.

Advantages of semi-automatic crisp ice cream maker machine

1. The commercial crispy waffle making machine has reasonable design and compact structure and is very popular in domestic and foreign markets. The machine has good safety performance, high efficiency, and large output. It is the ideal equipment for many ice cream factories, snack shops and high-end restaurants.

2. The semi-automatic ice cream cone machine only needs two people to operate at work, and the operation method is very simple. In addition, since all parts of the machine are made of high-quality 304 stainless steel, it has a long service life, low failure rate, and simple cleaning and maintenance.

3. The number of baking trays on the ice cream cone baking host is generally 6-18, and the model of the equipment is also determined by the number of baking trays. We can also customize the number of baking trays according to the actual production needs of customers.

4. The upper and lower heating plates of each baking tray are made of thick aluminum alloy plates and can withstand high temperatures. Moreover, the aluminum alloy plate has better heat conduction, which not only makes the processed egg rolls and cones uniform in color but also saves energy and electricity.

5. The PLC controller of this crisp ice cream cone making machine has an automatic counting function, which can automatically record the output of ice cream cones.